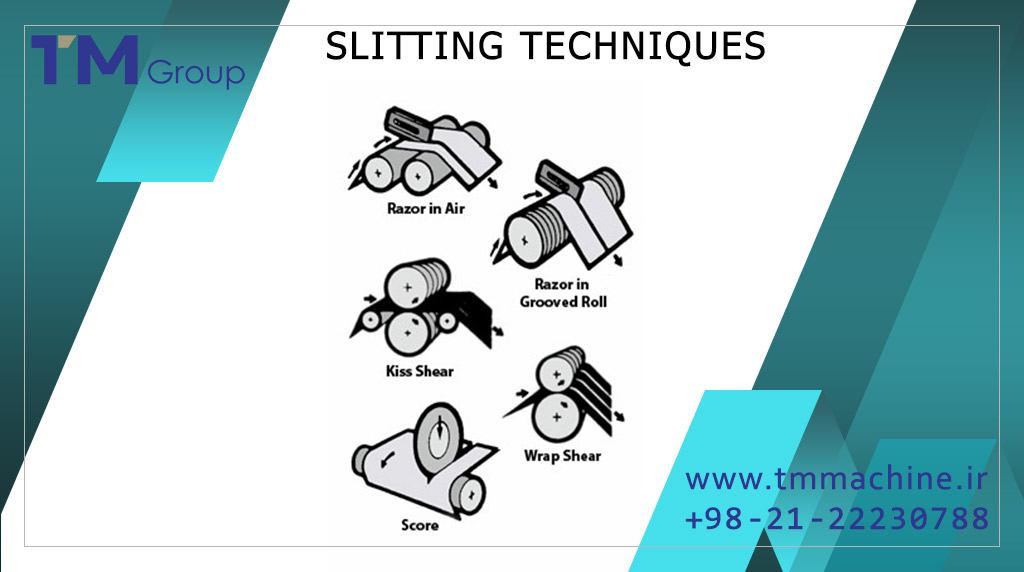

Slitter rewinder machines use three types of slitting techniques to cut material: razor blade, shear cut, and score cut. The most appropriate slitting technique to use depends on a variety of factors, such as the type and thickness of the materials being processed.

Slitting Techniques: A Basic Guide

Razor blade:

Used primarily with light and non-abrasive materials, this method employs a simple razor blade slit in the air or in a grooved roll.

Pros: This is the most economical method, along with having a fast and easy setup.

Cons: This method is not capable of easily cutting through heavy, rigid, or abrasive materials. At high speeds, the razor blade method can also burnish film. If enough heat is generated, it will melt the film, creating a bead that is detrimental to achieving good winding.

Shear cut:

This slitting method uses two rotary knives to produce the same cutting effect as obtained by pushing a pair of opened scissors through a sheet of paper. It is used for slitting heavier gauge material such as thicker film/sheet, paper, foil, and most laminates.

Pros: The benefits of this method include accurate slit widths and close tolerances.

Cons: The setup for this method needs to be extremely precise, and requires achieving an ideal angle at the junction of the blades.

Score cut:

Also referred to as “crush cut”, the score cut method is the oldest form of cutting and the first employed in slitter rewinder machinery. It involves crushing the material to sever one part from the other by using a dull knife making contact with a hard surface. This method is ideal for slitting pressure-sensitive adhesives, since it creates a “dry,” non-sticky edge.

Pros: Quick setup is a major advantage of this method.

Cons: When the score cut method is used to slit paper material, it creates dust that can accumulate and cause equipment malfunction. Also, if a defect appears when slitting plastic film and sheet, this can create film stretching and deformities (leading to rejects). When used on hard plastic, it may cause cracking.

While this information will help you determine which methods may be best for your application, it’s important to keep in mind that every project has different goals and uses varying machinery, materials, and processes

.

TM Group is the main manufacturer of printing machinery in Iran which in addition to Iran domestic market, supplies to Arab countries, CIS and MENA region. For inquiries and purchases please contact us here.

We also invite you to visit PrintMachine.Market to buy and sell new or used machines.